- A Complete Emission Control Program

- Crankcase Ventilation

- Diesel Emissions

- EGR Components

-

EVAP Emissions

- About EVAP Emissions

- Canister Purge Solenoids

- Canister Purge Valves

- Canister Vent Solenoids

- Canister Vent Valves

- Evaporative System Integrity Modules (ESIM)

- Fuel Vapor Canisters

- Fuel Vapor Leak Detection Pumps

- Idle Air Control (IAC) Valves

- Vapor Canister Filter

- Vapor Canister Purge Pumps

- Vapor Canister Vent Hose

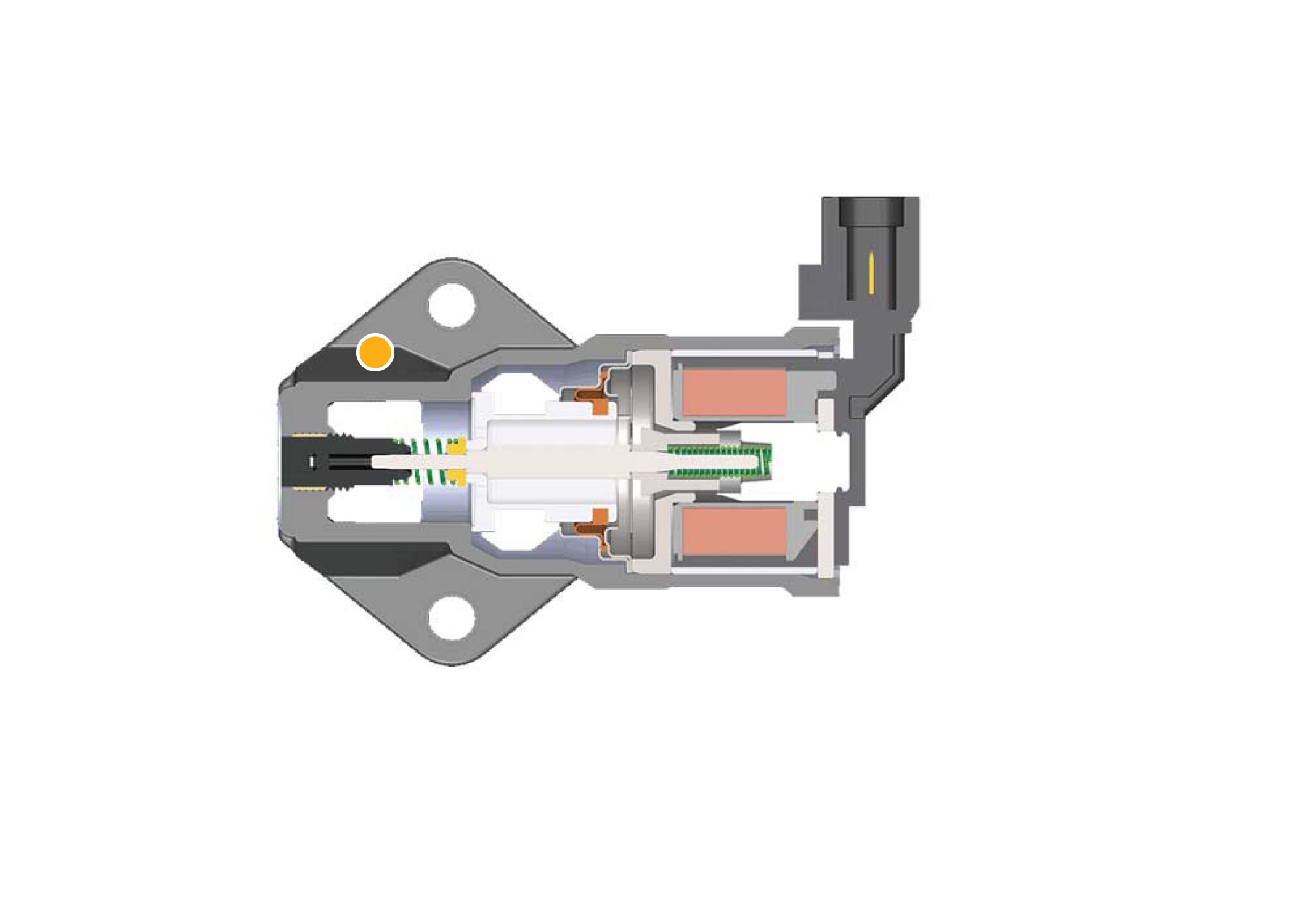

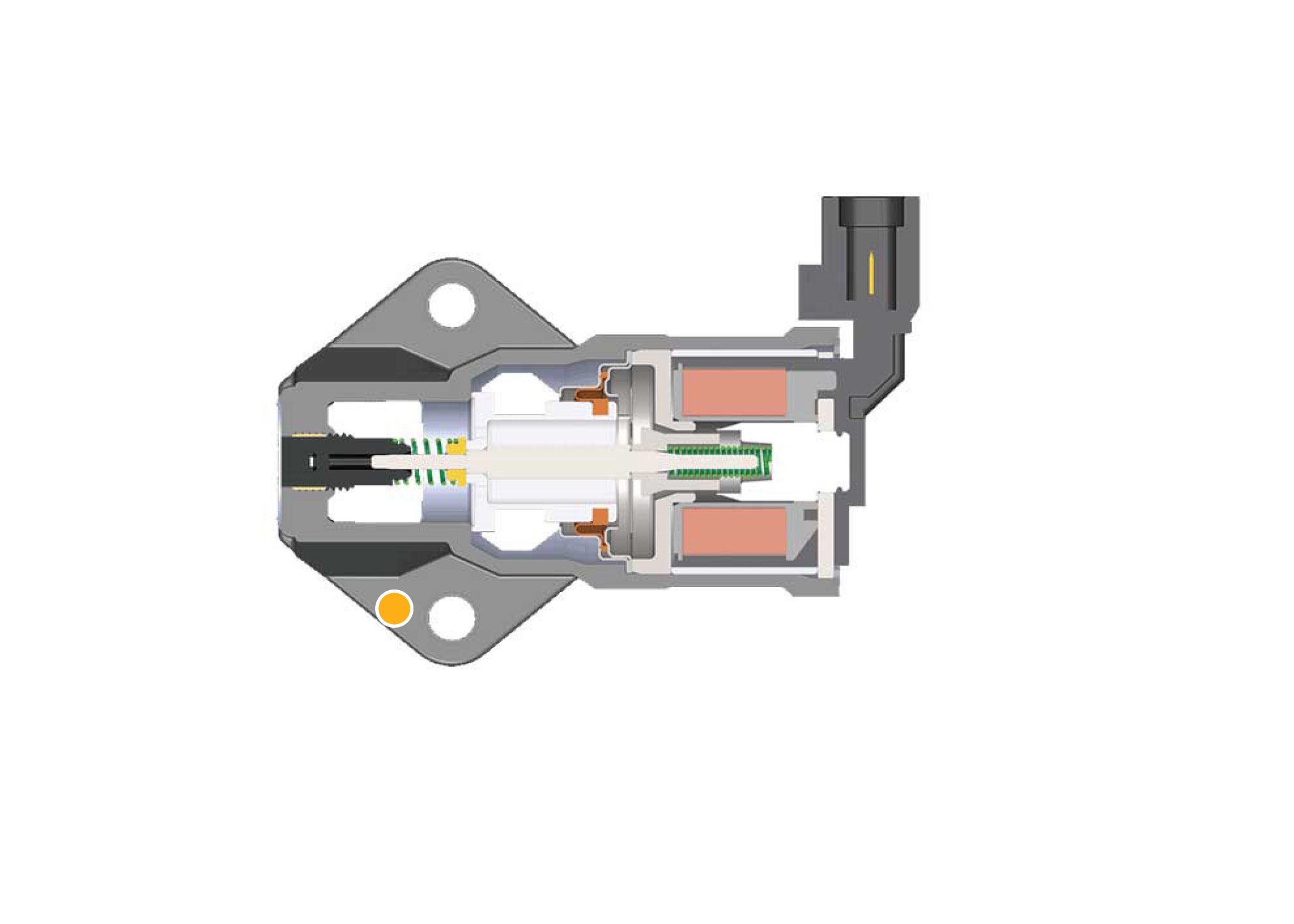

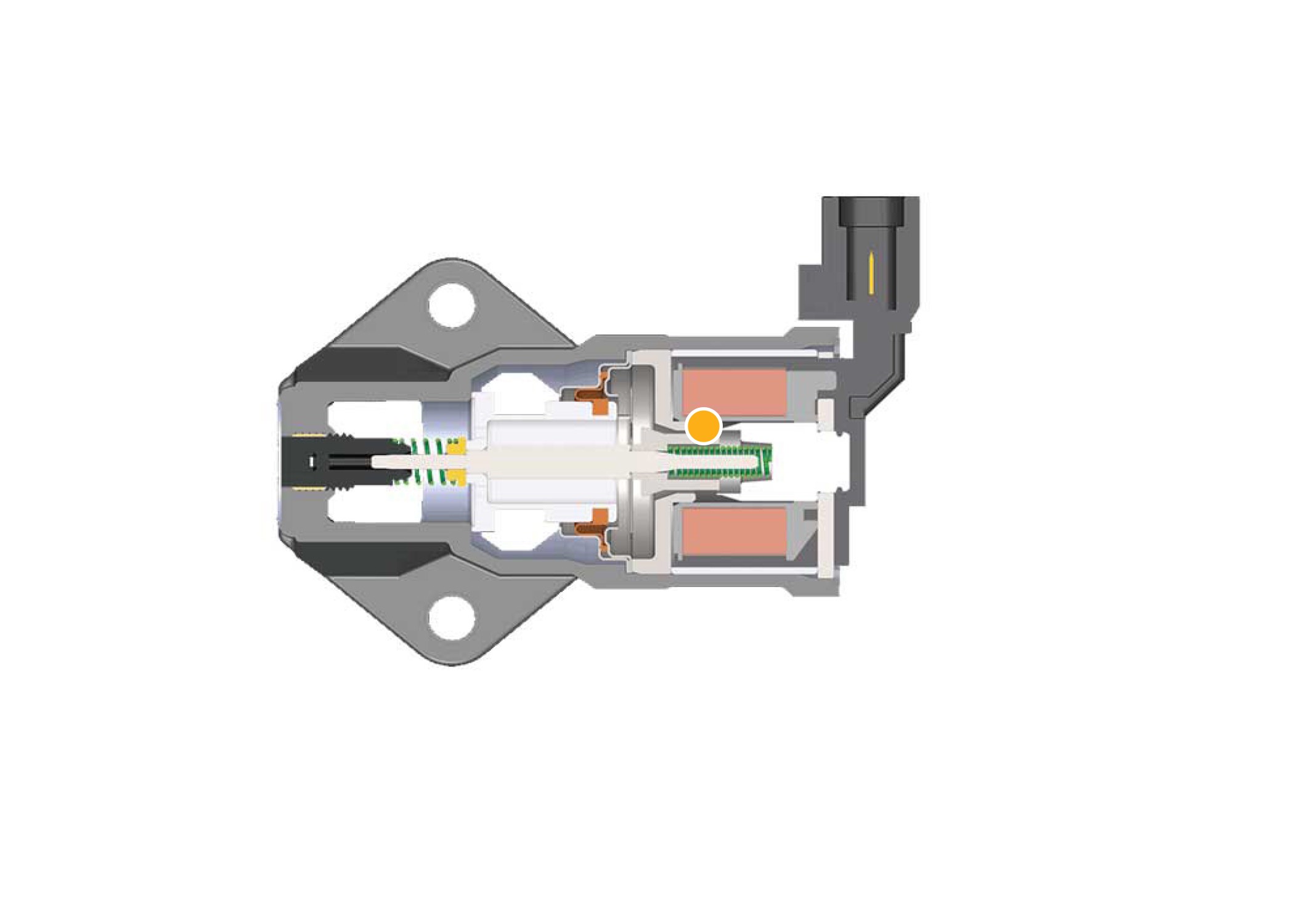

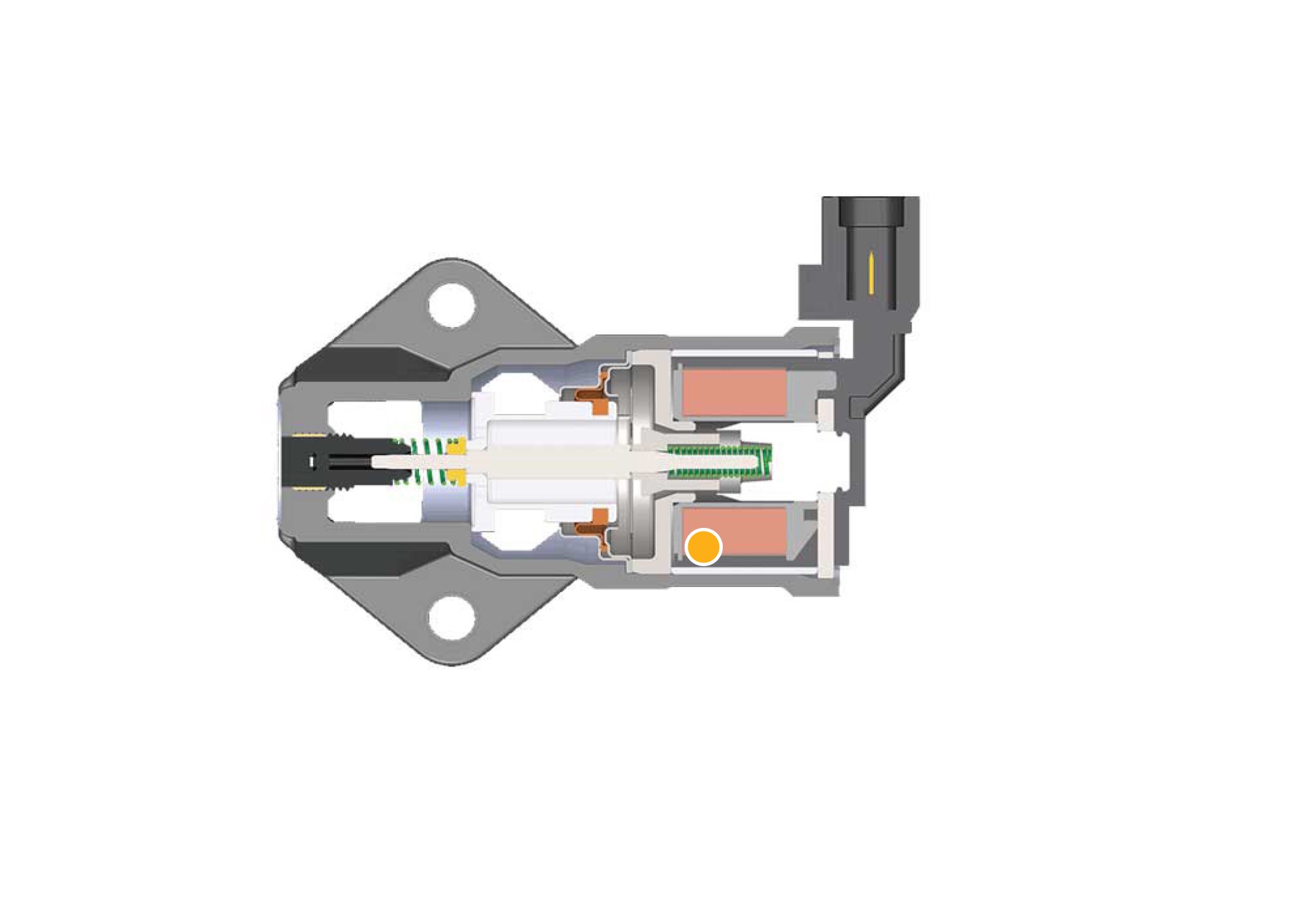

Idle Air Control (IAC) Valves

The idle air control (IAC) valve is located on the throttle body of fuel-injected engines. This valve works with the vehicle’s ECU to electrically regulate airflow to the engine to ensure smooth idling.

Standard® manufactures Idle Air Control Valves at our ISO 9001 and IATF 16949-certified facilities in Greenville, SC, and Reynosa, Mexico, respectively. A key aspect of the manufacturing process is load testing, which makes sure each actuator delivers a greater force than the actual load.

Takeaways

- Tested at greater than normal force to extend longevity

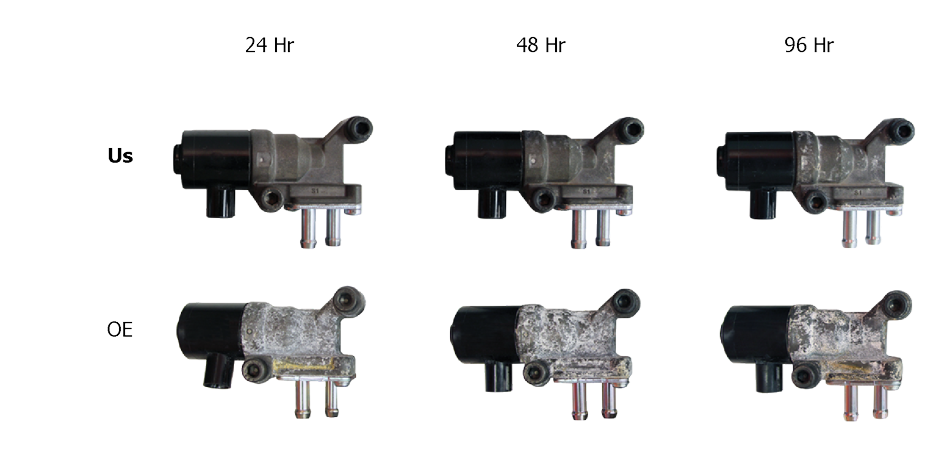

- Anodized aluminum housing resists wear and tear from corrosion

-

Precision-machined housing ensures proper air flow to engine as required by ECU during changing load requirements

-

Anodized aluminum housing resists corrosion better than regular passivation treatment

-

Precision-machined solenoid components generate magnetic force to actuate plunger

-

High-temp polyester coating on solenoid coil wire ensures proper function during cyclic exposure to elevated temperatures

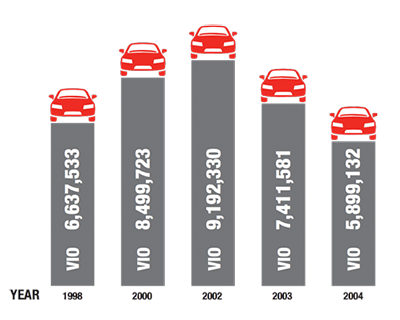

A Sweet-Spot Category

More than 70 million vehicles (model years 1995 through 2005) on the road today have entered “sweet spot” years for IAC repairs, according to our research. This means they have an IAC that will need to be replaced soon.

Choose high-quality Standard® Idle Air Control (IAC) Valves to take advantage of this growing repair opportunity.

Designed and Tested to Prevent Corrosion

Honda 3.5 Liter Idle Air Control Valve Replacement

This video demonstrates replacing the idle air control motor for a 3.5 liter application.

Level of difficulty: ADVANCED

Approximate installation time: 1 hr

Tools needed: Phillips screwdriver

Additional parts: antifreeze, throttle body gasket, and/or intake manifold gasket