-

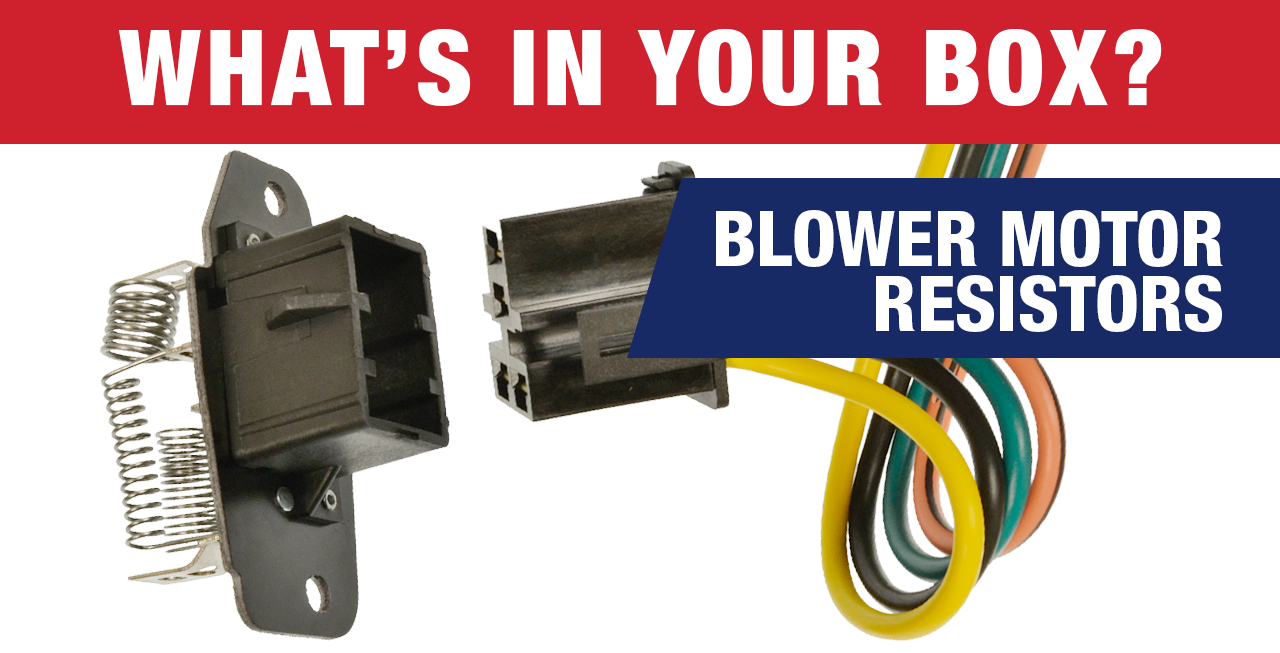

What's In Your Box

- History, Trusted Brands & Training

- Manufacturing, Engineering & Testing

- Parts are Just Parts?

- ABS Speed Sensors

- ADAS

- Blower Motor Resistors

- Blue Streak Import Coils

- Blue Streak Kits

- Camshaft & Crankshaft Sensors

- Collision Repair Program

- Electronic Throttle Bodies

- EV / Hybrid Program

- EVAP Components

- Gas Fuel Injection

- GDI Injection

- Ignition Coils

- Oil Filter Housing Kits

- Oil Pressure Switches

- Parking Brake Actuators

- TPMS

- Turbocharger Kits

- Variable Valve Timing

- Resources

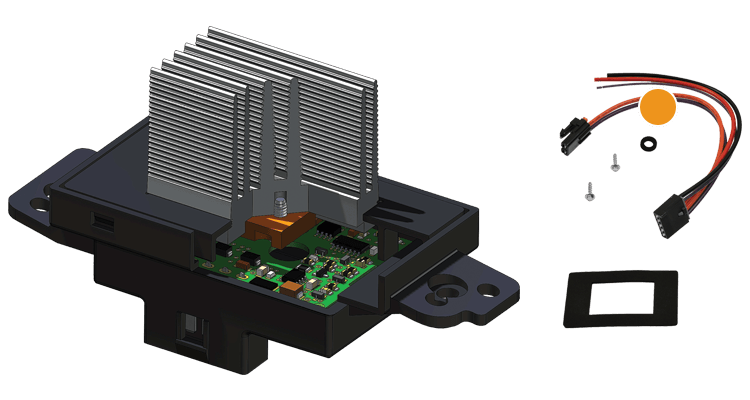

- More than 750 Blower Motor Resistors and Kits for domestic and import applications

- Blower Motor Resistors use the highest-quality components that match the original fit, form and function

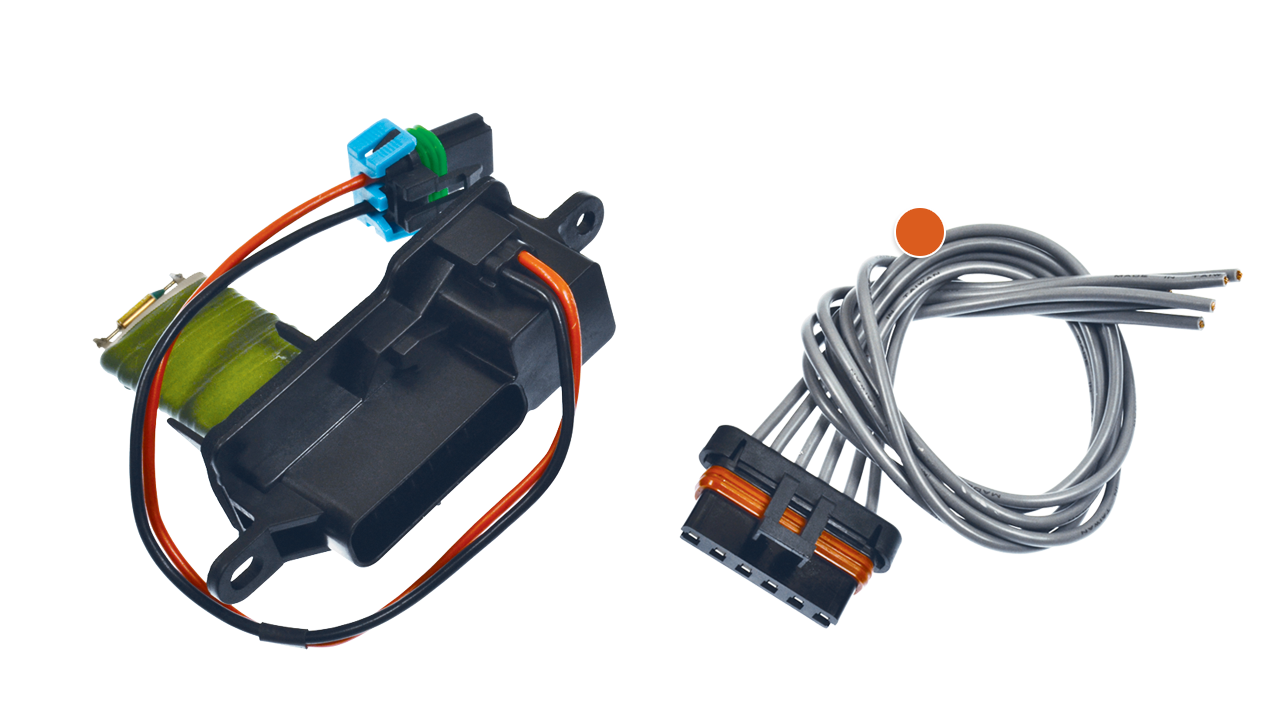

- Blue Streak® premium BMR kits feature connectors withstand excessive heat and prevent melting

Blower Motor Resistors and high-temp BMR kits are manufactured in our IATF 16949-certified North American facilities.

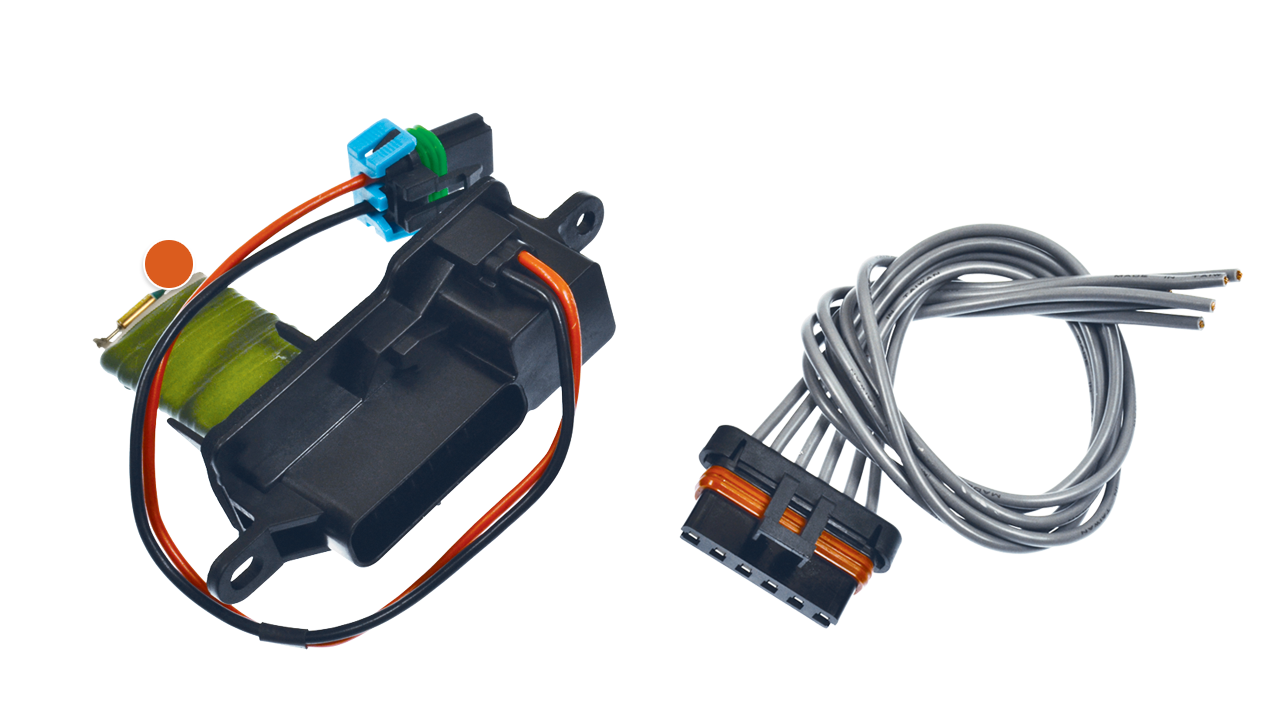

In addition to our full line of the highest-quality Standard® and Blue Streak® Blower Motor Resistors, we’ve engineered a line of problem-solving, high-temp connectors and kits.

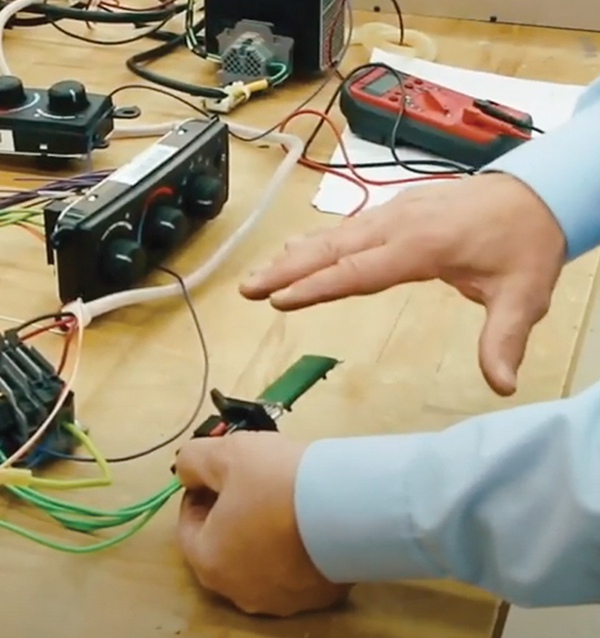

Blower Motor Resistor Testing

Our Engineers sample-test every blower motor resistor for draw, resistance and RPM. Test samples are validated to precisely match the OE specs and meet or exceed the OE for durability. We examine performance at all speeds, and then conduct 48-hour load tests.

It’s how we know our blower motor resistors will operate at peak performance and deliver a long service life under all operating conditions.

Blue Streak® Blower Motor Resistor kits feature a problem-solving, high-temp harness.

We improved on the original, engineering a high-temp connector that withstands excessive heat and the extreme current that can melt an inferior resistor or connector.

-

Kanthal D resistor wire provides longer life for higher watt resistors

-

Precision-built resistor coils for better fan control

-

Tin-plated steel terminals ensure maximum contact and excellent fit

-

Made from high-quality ceramics with copper electrical connectors for accurate resistance values

-

Thermally protected with on-board fuse

-

Thermal-cycle tested -22°F to 257°F

-

TXL copper wiring withstands high electric current to protect against heat-related failure

-

High-temp connector prevents melting under extreme temperatures

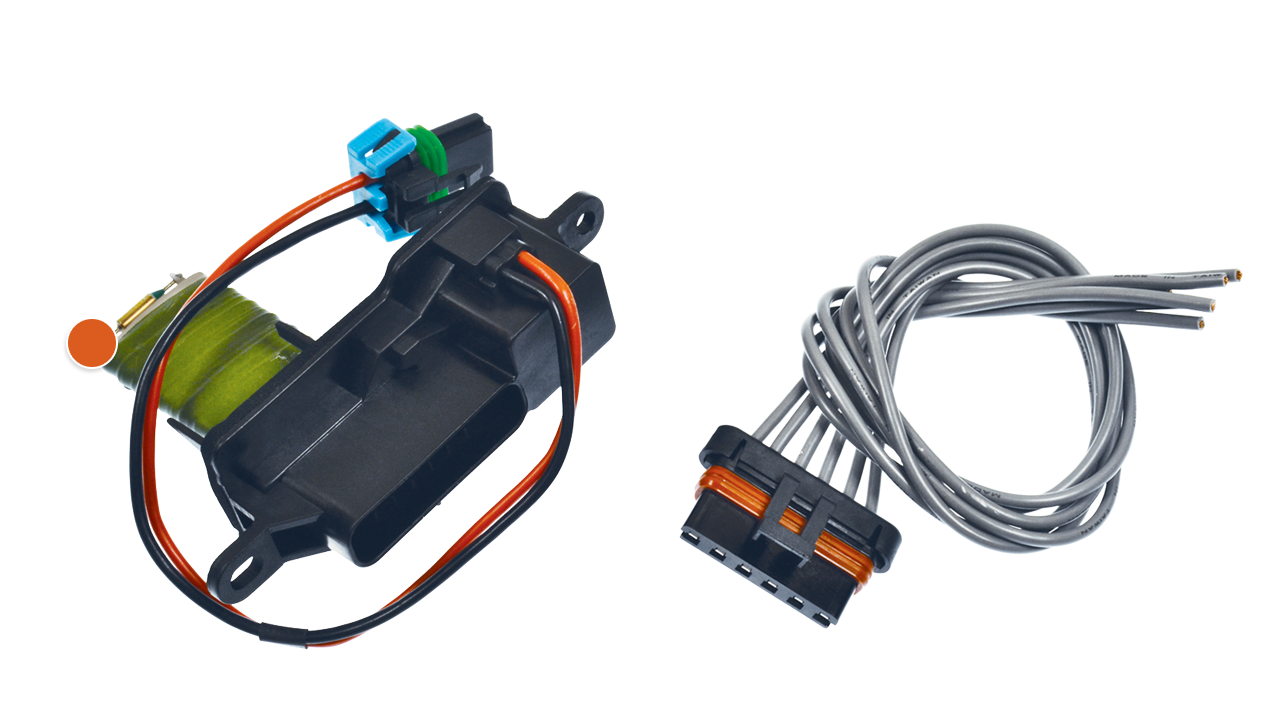

Engineered to prevent water damage and perform reliably, every time.

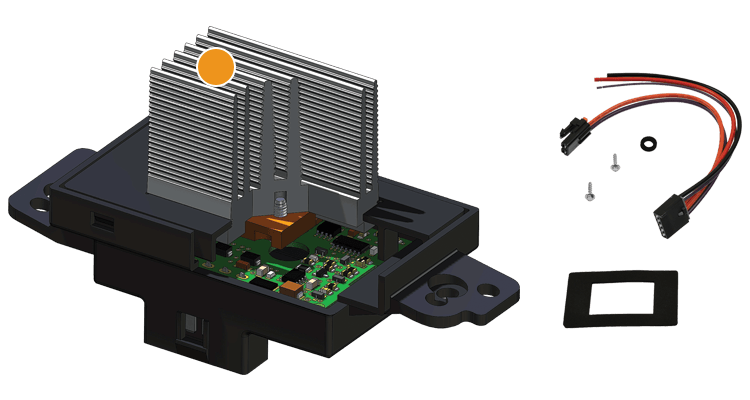

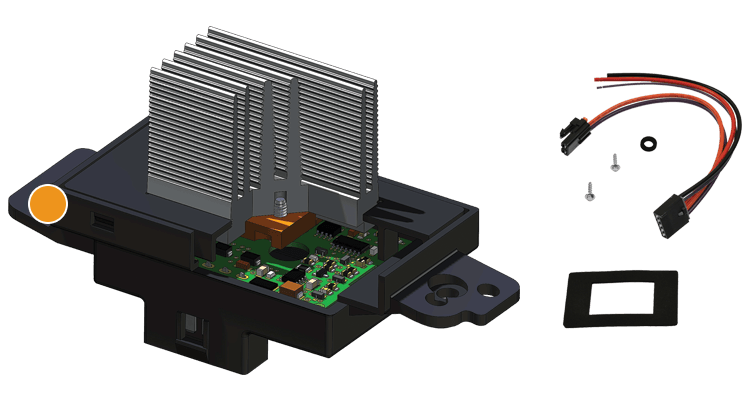

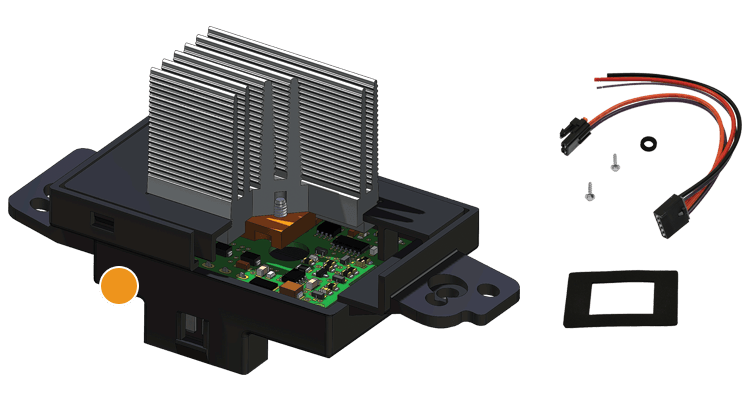

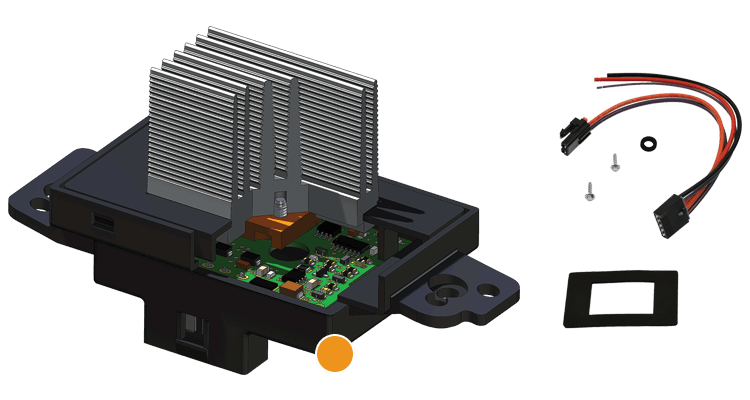

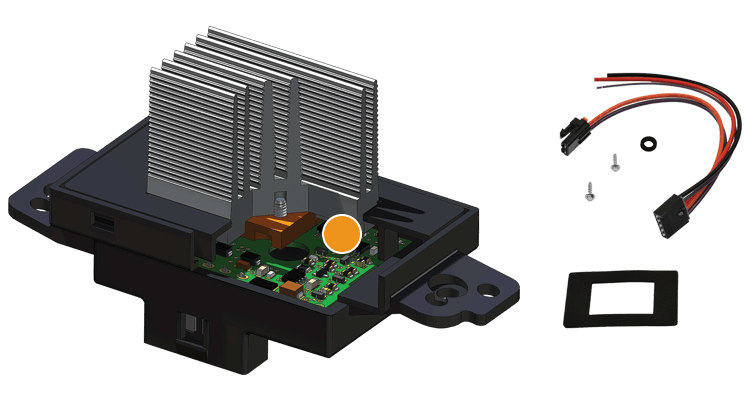

Our RU631 Blower Motor Resistor features several improvements over the OE, including an umbrella cover design that prevents water intrusion and a larger-output power device and upgraded two-ounce copper board that protects against overheating.

-

Larger output power device mounted directly to heat sink improves heat dissipation

-

Improved umbrella cover design prevents condensation from entering module

-

RTV sealant around heat sink and cover perimeter prevents water intrusion

-

Manufactured in the USA

-

Upgraded 2 oz. copper board increases conductivity and power dissipation to prevent overheating

-

Included wire harness undergoes voltage drop testing to ensure performance

Tech Tip: Check the connector when replacing a blower motor resistor.

Be sure to inspect the mating connector for signs of damage caused by excessive heat. If damaged, replace with a problem-solving Blue Streak® blower motor resistor kit or a premium Standard® connector.

For more than 100 years, when the OE failed, technicians have trusted Standard® and Blue Streak® to deliver a part that’s equal to or better than the original it’s replacing.