About Ignition Coils

Ignition Coils

As the aftermarket leaders in ignition coils, Standard® offers full-line coverage for all makes and models, with the trusted quality and performance that only comes with over 100 years of experience. This product category will be at the forefront for years to come. Standard® is leading the way with an expansive selection of quality ignition components, including cassette coils, coil-near-plugs, coil packs and coil-on-plugs.

Elite Manufacturing and Testing

Standard® engineers and manufactures high-quality ignition coils and ignition components at SMP’s 60,000 sq. ft. facility in Bialystok, Poland.

Highlights of the IATF 16949 and ISO 9001-certified facility include lean manufacturing methods and vertically integrated manufacturing processes that include multi-spindle winding, injection molding, potting, curing and welding.

To ensure quality, all products manufactured at the facility undergo a full spectrum of measurement and life testing in addition to a full range of environmental analysis that includes thermal shock, thermal cycling, salt spray, vibration and storage tests.

Ignition Coil-on-Plug (COP)

The ignition coil converts a low-voltage current to high-voltage energy that is delivered to the spark plug to ignite the air/fuel mixture within the cylinder. A coil-on-plug performs the functions of both the ignition coil, which creates the spark energy, and the spark plug wire set that is designed to contain and deliver the high-voltage energy to the spark plug. Standard® Coil-on-Plug assemblies are engineered and tested to meet or exceed OE standards for spark energy, impedance and durability.

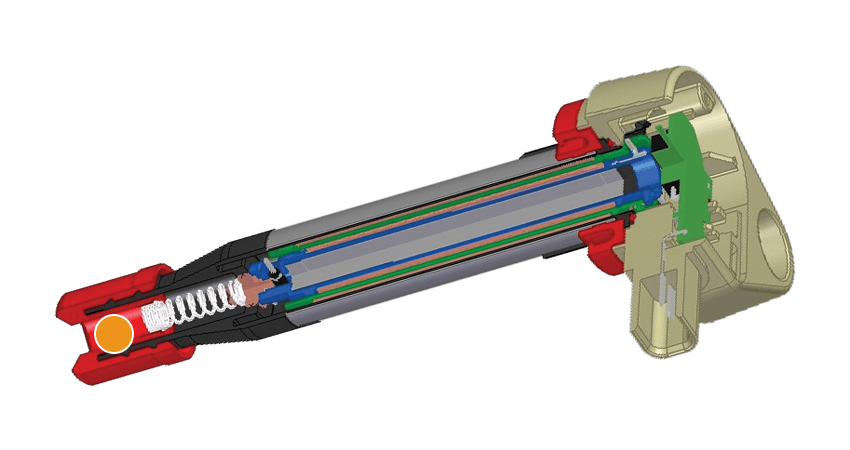

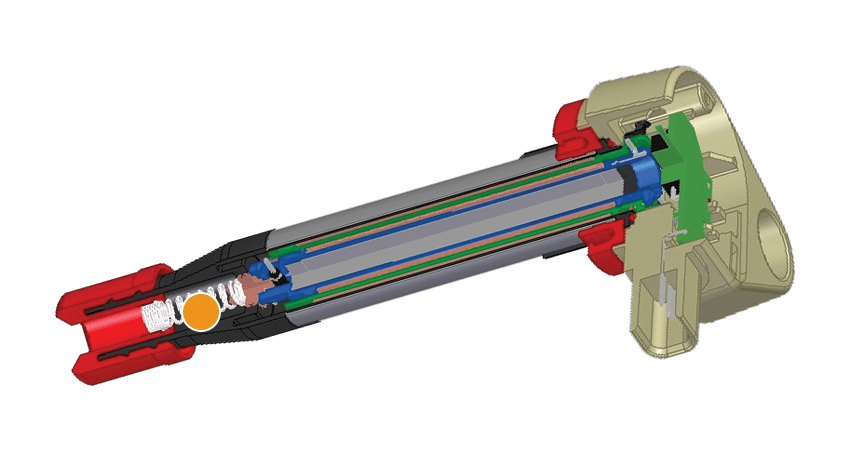

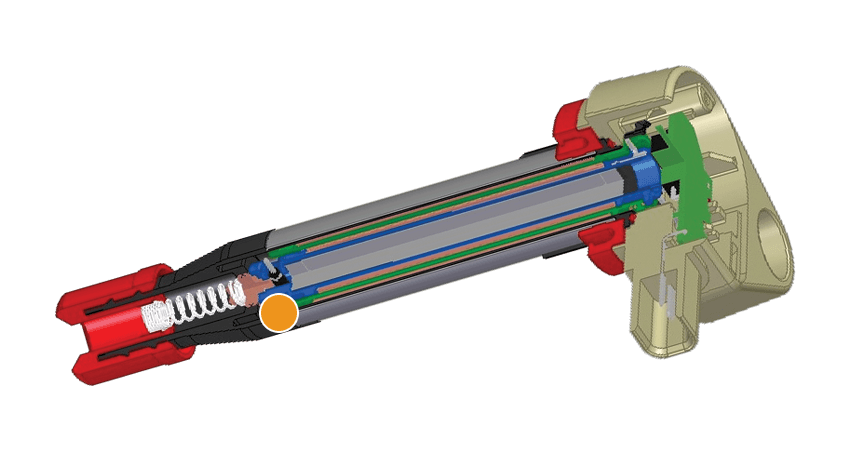

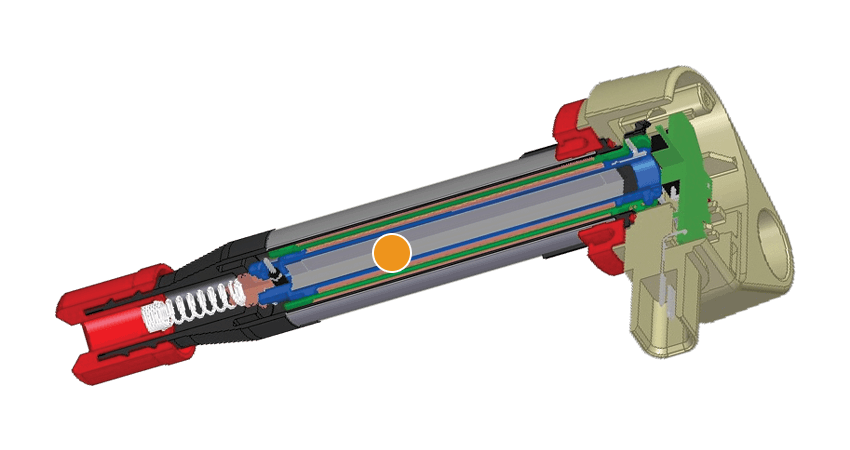

Pencil Coils

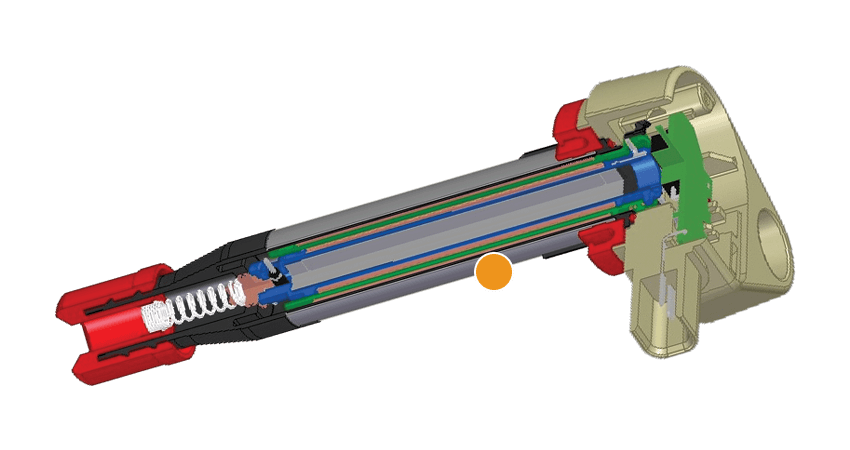

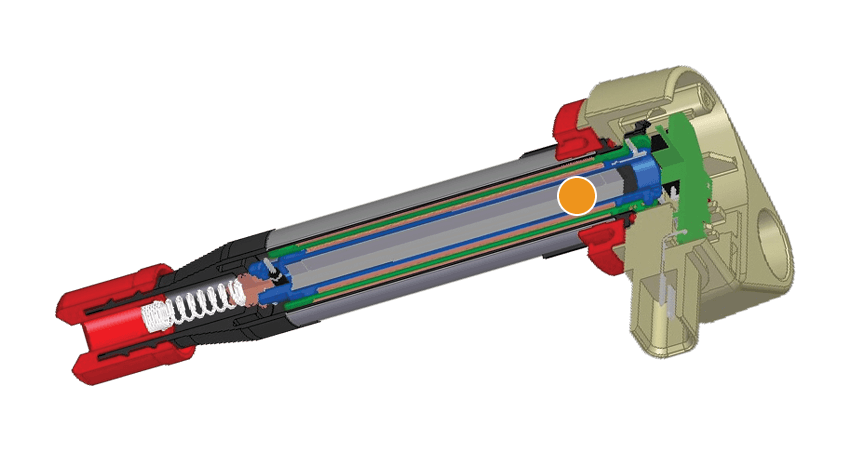

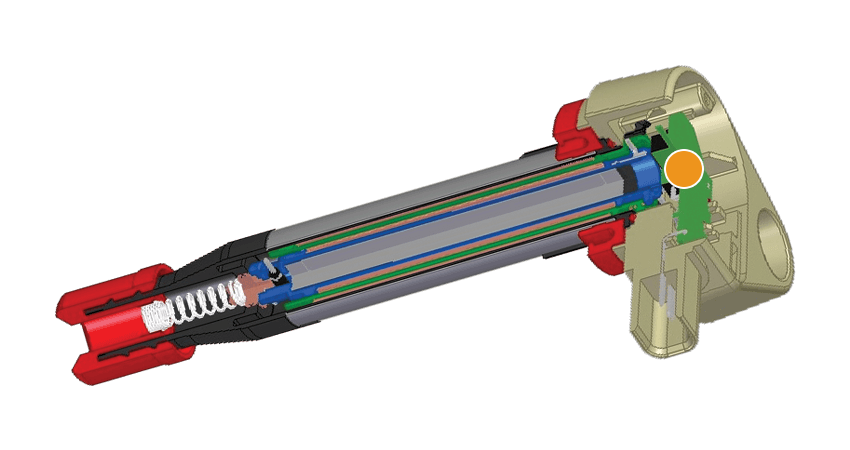

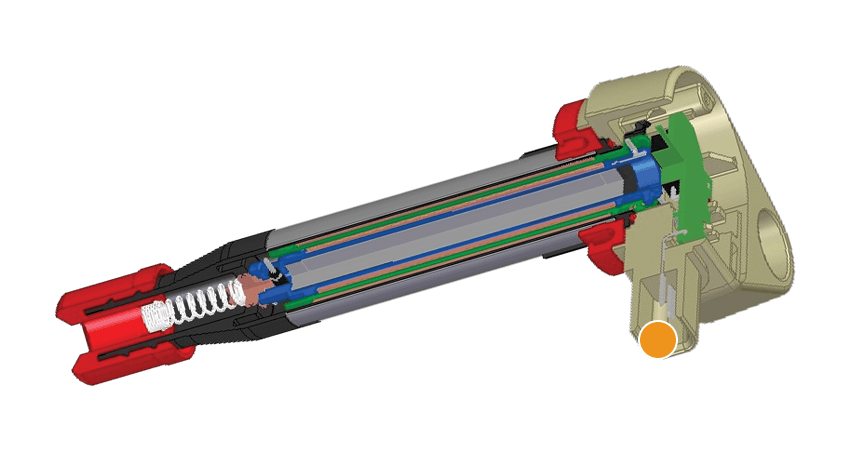

As engine technology evolves, coil-on-plug technology will continue to play an increasingly important part in ignition systems. One such technology is the pencil coil. Standard® is leading the way with quality parts and exceptional coverage for this growing category. Take our UF242 Ignition Coil, for example:

Tech Tip: If there’s been a failure, such as a short, we recommend replacing the spark plug while you’re replacing the pencil coil.

-

Silicone rubber boot withstands extreme heat and provides superior insulation

-

Stainless steel spring resists corrosion

-

Primary and secondary bobbins made from fiberglass-reinforced polyethylene terephthalate prevent voltage flashover for extended service life

-

Internal core made from grain-oriented electrical steel limits loss factor within magnetic circuit to reduce heat that may affect coil endurance

-

External core made from oriented silicon steel for durability

-

Neodymium magnet produces max high-voltage output at all speeds

-

Electronic ignition module profile and feedback signal matches fit, form and function of original

-

Tin-plated brass terminals improve electrical contact and protect against corrosion

Water Intrusion and Premature Coil Failure

A common problem on some GM models (4.2 inline 6 cyl. LL8 VIN code S – PRO LL8) is water intrusion that causes premature failure of the coil and spark plugs. But it's not a coil problem!