Attention To Details

Intermotor® is a complete engine management import line with more than 20,000 parts and a commitment to exact-match fit, form and function. It's recognized as the import leader in coverage and quality.

About Intermotor®

Intermotor® is a complete engine management import line recognized as the import leader in coverage and quality, with a commitment to exact-match fit, form and function. What might not be immediately apparent is the design, engineering, manufacturing expertise and QC testing that goes into every Intermotor® part. Our attention to the extra details is at the heart of Intermotor® excellence and what separates Intermotor® from the rest.

The Intermotor® line now numbers more than 20,000+ parts and growing. Intermotor® is your complete engine management import line with a concentration on high-technology categories such as computerized engine controls, fuel injection and emission controls. We have coverage for virtually every vehicle with an import nameplate. Delivering premium quality import parts for decades has earned Intermotor® the reputation as the reliable brand for genuine import parts.

And with manufacturing locations around the world, Intermotor® truly is a global leader in import parts. That’s why no other import brand can match Intermotor® and why Intermotor® is The Import Leader by Design.

The Import Leader by Design

Intermotor® is a complete engine management import line recognized as the import leader in coverage and quality, with a commitment to exact-match fit, form and function. What might not be immediately apparent is the design, engineering, manufacturing expertise and QC testing that goes into every Intermotor® part. Our attention to the extra details is at the heart of Intermotor® excellence and is what separates Intermotor® from the rest.

Intermotor® is the import leader in coverage and quality with a commitment to excellence designed into every product detail. Check out the examples below to learn about of the details that make Intermotor® the Import Leader by Design.

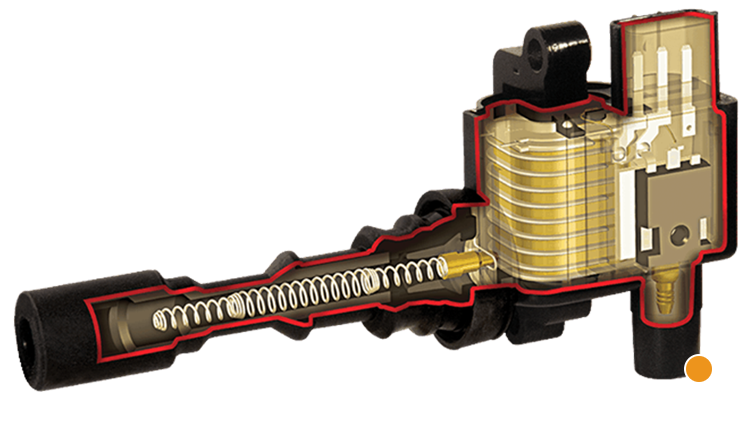

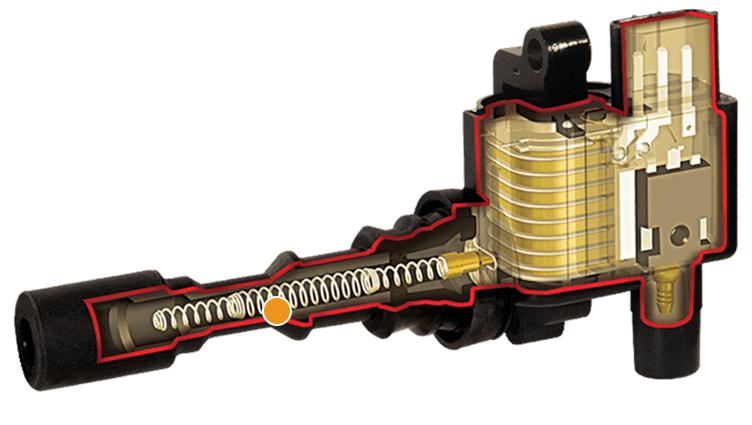

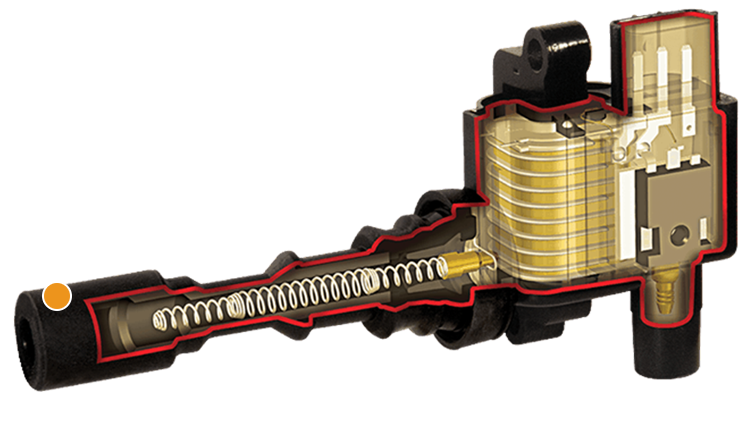

Intermotor Fuel Injectors

Designed For Special Delivery

Intermotor® fuel injectors are flow-matched to each specific application, with advanced laser-drilled metering holes that deliver precise flow and spray patterns for proper injector performance under all conditions. Our fuel injectors are manufactured in our ISO 9001-certified, Greenville, SC facility and 100% tested for coil resistance, injector leakage, static and dynamic flow. It all adds up to the performance you expect from the premium import leader.

-

High-Temperature Viton® External O-rings enable proper sealing under extreme conditions

-

Tin-plated brass terminals for increased corrosion resistance

-

Stainless steel calibration pin and spring assembly prevents corrosion within fuel control body

-

Solenoid coil windings are precision wound and trimmed to allow application specific resistance values

-

Valve seats machined to a one-micron finish for a leak-proof seal

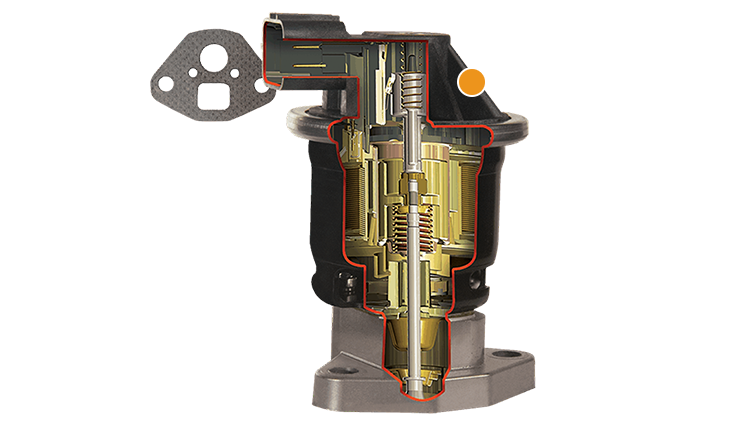

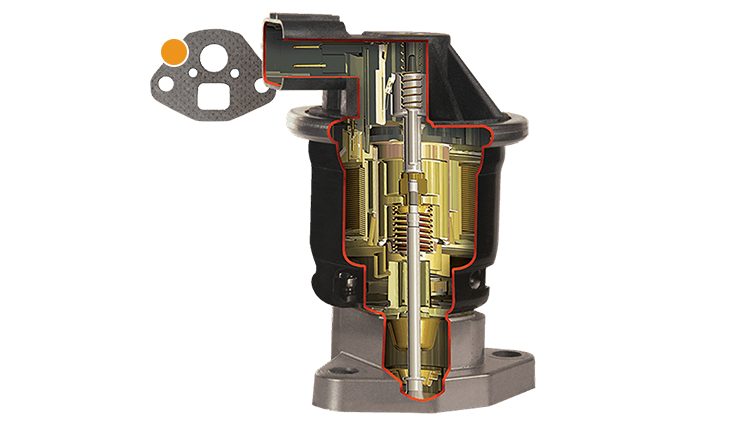

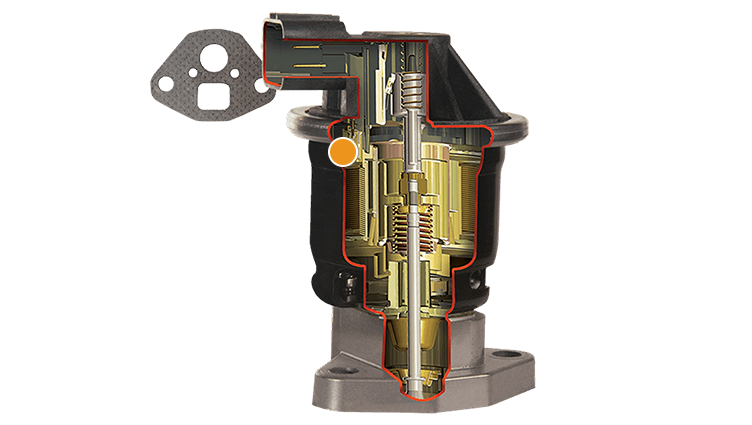

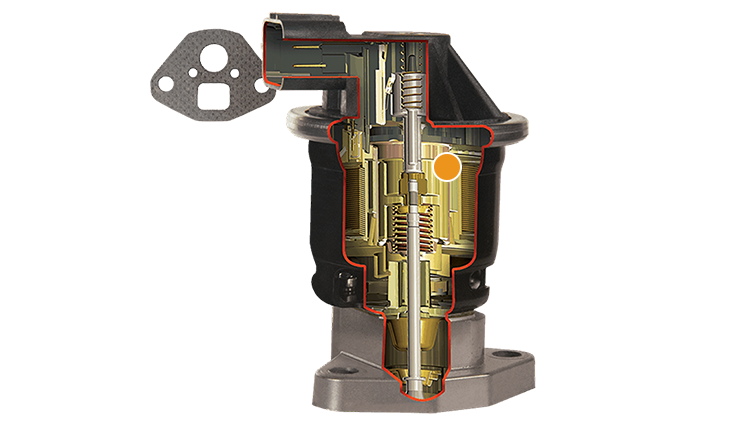

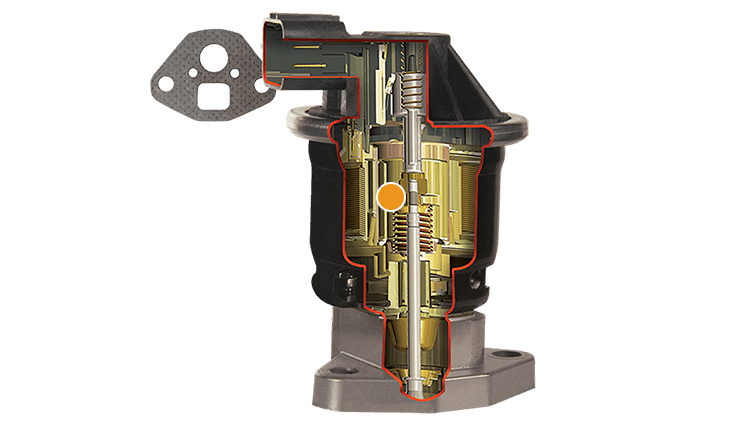

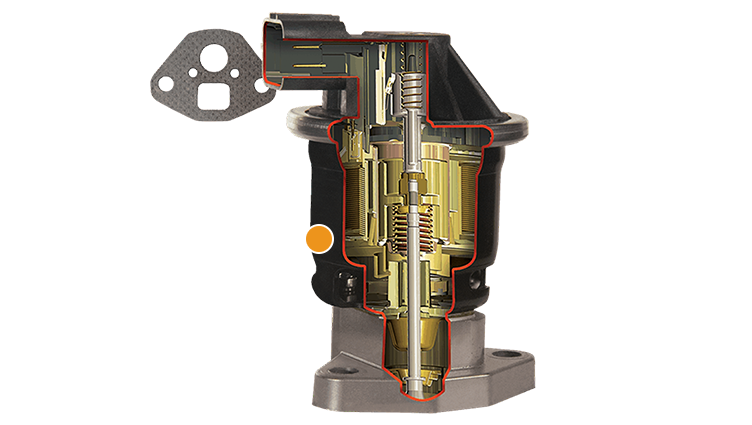

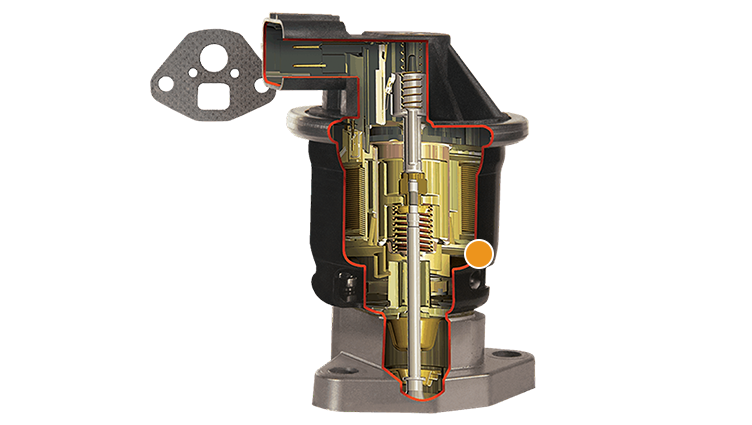

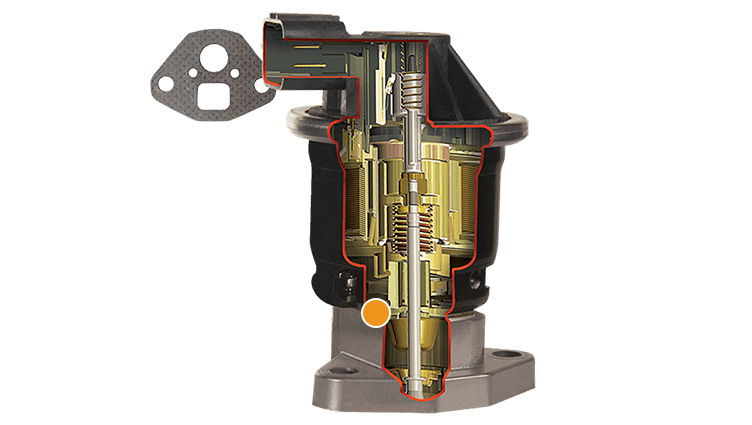

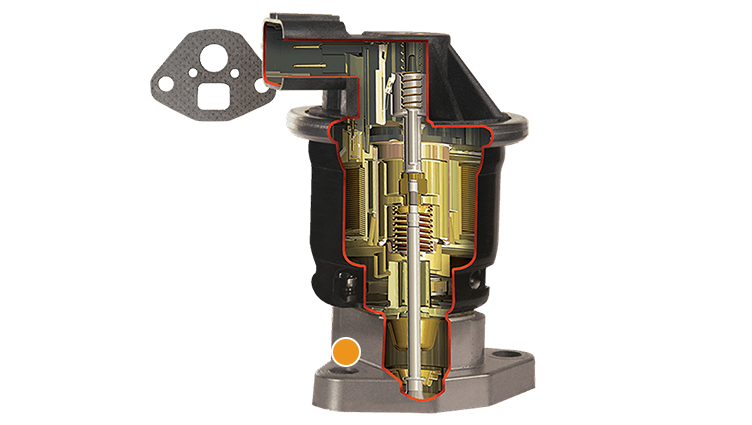

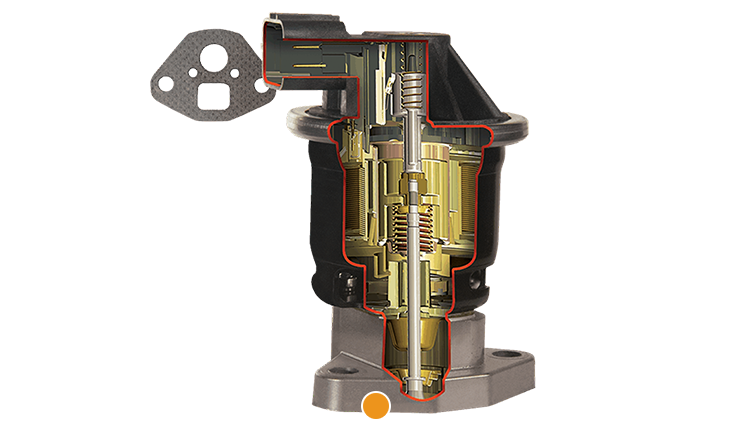

Intermotor EGR Valves

Designed To Go The Distance

At Intermotor®, every part we design features thoughtful details that elevate it above the competition. Our EGR Valve Sensor contacts are made with a precious metal alloy that withstands millions of duty cycles. They are manufactured and 100% factory tested for proper flow, solenoid resistance, response time and leakage in our IATF 16949 certified, Independence, KS facility. It’s this commitment to excellence that makes us the premium import leader.

-

Injection-molded high-temperature polymer to prevent high-temperature failure rate

-

Flexible graphite gasket

-

Sensor contact made of precious metal alloy to perform millions of duty cycles

-

Heavy-duty solenoid provides extended service life

-

All stainless steel internal components resist corrosion

-

EGR Valves are designed as direct-fit OE replacements

-

Stainless steel internal components and fully encapsulated copper windings and connections on electronic EGR valves ensure precision operation and greater protection

-

Sintered metal technology ensures a consistent, precise fit of valve seat for accurate flow control

-

EGR Valves utilize palladium/gold/platinum alloy with a Teflon®-based lubricant to ensure very low contact resistance

-

Improved anti-rust coating on the machine casting for additional protection against rust for maximum life

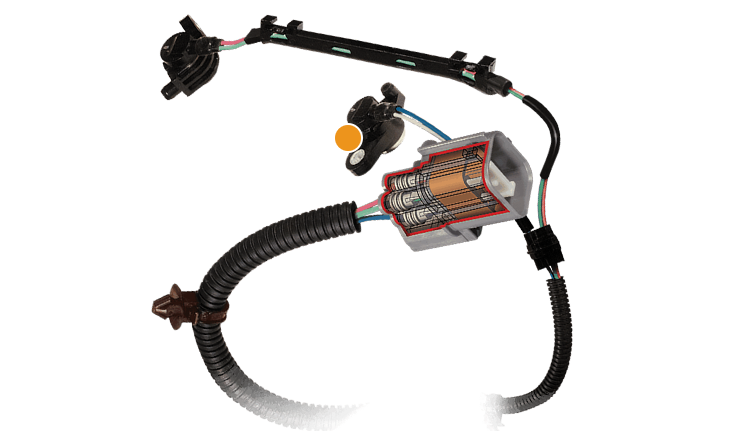

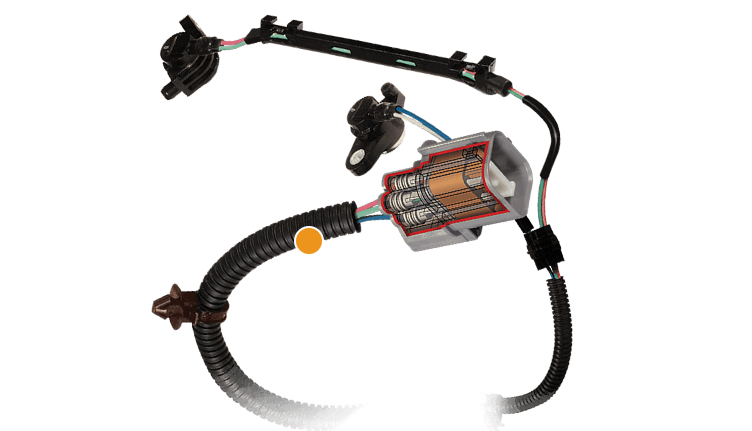

Intermotor Crankshaft Sensors

Designed For Perfect Timing

At Intermotor®, we design the details that deliver superior quality and performance. Manufactured in our IATF 16949-certified, SMP® Reynosa, Mexico facility, our Crankshaft Position Sensors feature matching connectors and tin-plated brass terminals to ensure an accurate, watertight connection to the wiring harness. With 100% end-of-line testing to ensure proper timing, pulse width and signal amplitude, it’s no wonder Intermotor® is the import leader by design.

-

High-strength, Neodymium magnets ensure proper signal voltage to the ECM

-

Factory-Installed Grommets and Wire Clips on the harness ensure proper mounting during installation

-

High-strength, Neodymium magnets ensure proper signal voltage to the ECM

-

Factory-Installed Protective Loom for added protection

-

Factory-installed Grommets and Wire Clips on the harness ensure proper mounting during installation

-

Matching connectors and tin-plated brass terminals ensure accurate, watertight connection to the harness

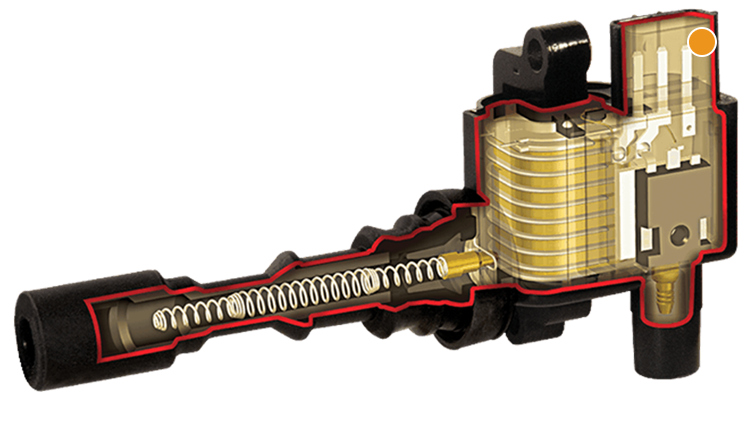

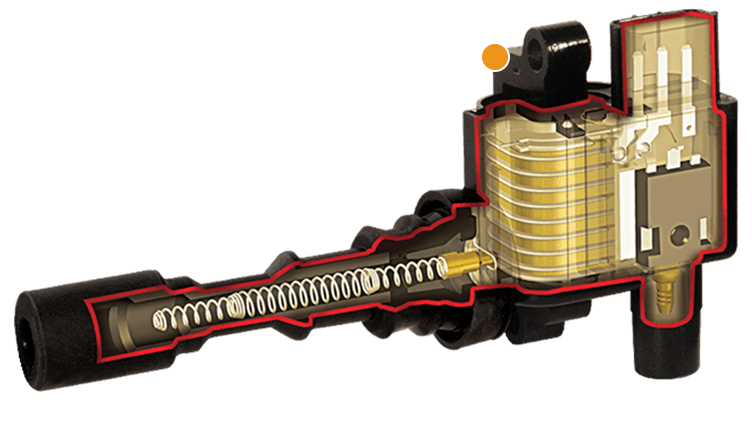

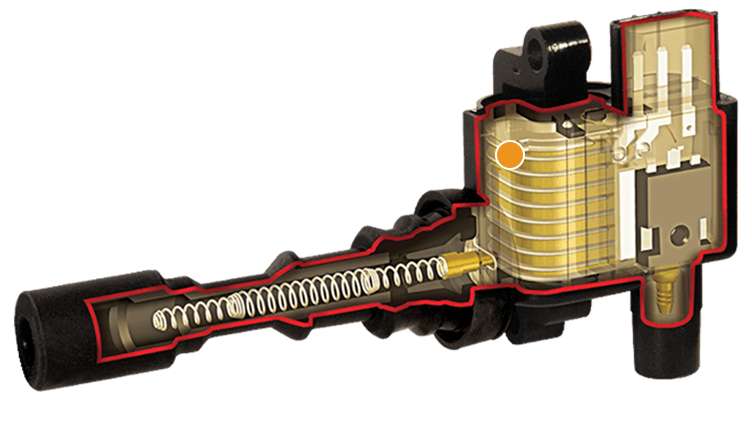

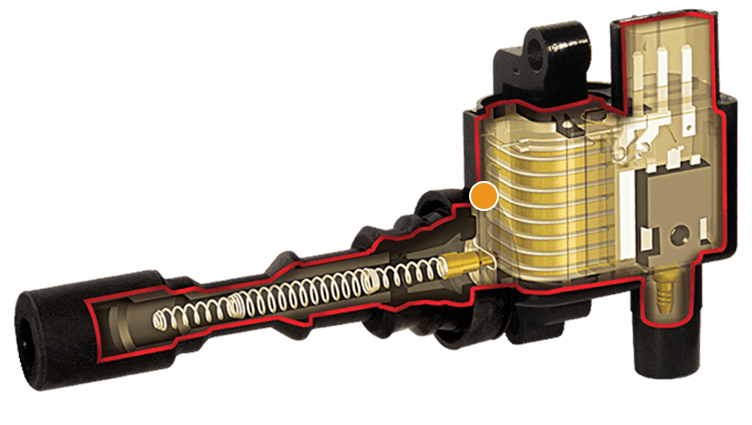

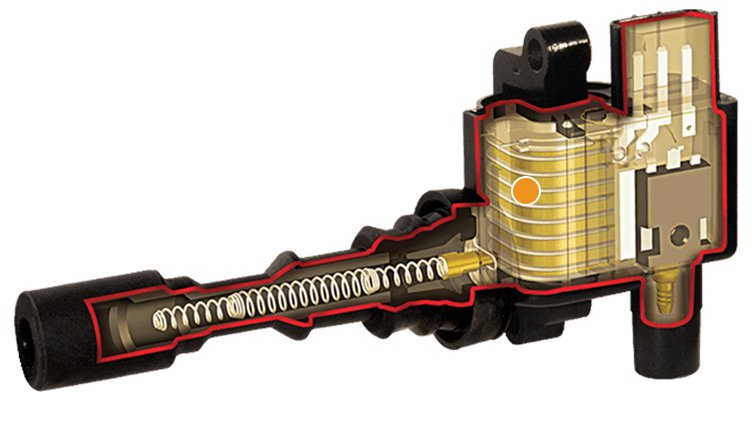

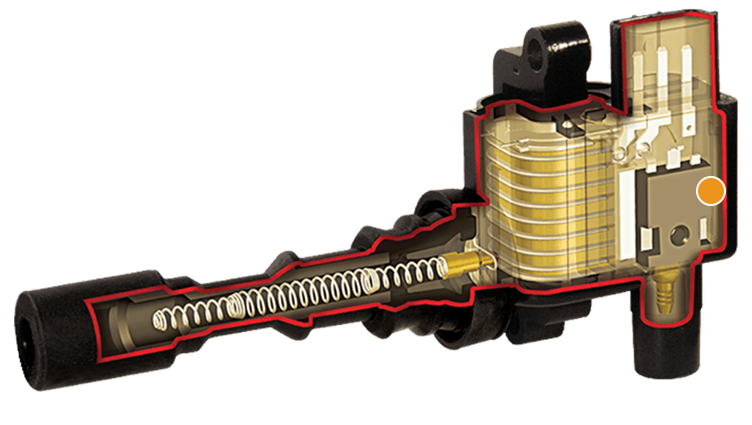

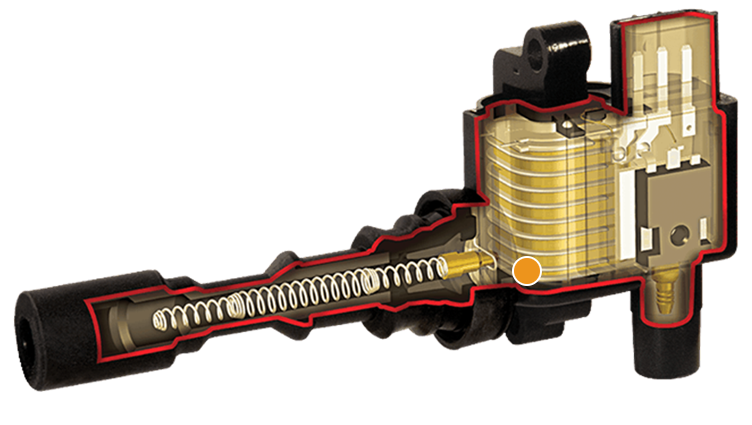

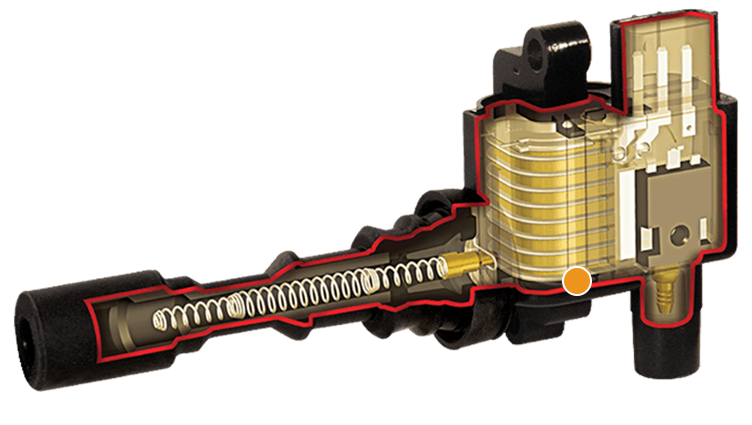

Intermotor Coil-on-Plug Assemblies

Designed to Take the Heat

Manufactured in SMP’s ISO 9001 and IATF 16949-certified, Bialystok, Poland facility, our specially formulated epoxy is high temperature and shock resistant to handle rapid changes in engine temperature and prevent cracking or coil damage. Engineered to bond with the coil housing and bobbins, our unique process eliminates air pockets and prevents moisture intrusion and thermal breakdown. It’s just one more design detail that makes us the import leader by design.

-

Tin-plated brass terminals for corrosion protection and improved electrical contact

-

Samarium-cobalt magnet in the core creates a strong magnetic field for maximum high voltage output at all speeds

-

Primary coil winding made of 200°C/392°F insulated premium 25-gauge copper wire — engineered and precision wound to generate a strong magnetic field for improved performance

-

Improved secondary windings using ETP copper wire provides maximum voltage conductivity

-

Reinforced bobbins and additional winding bays prevent internal arcing, high voltage breakdown, and voltage flashover

-

Exact-match electronic module feedback signal

-

Bobbin is made from polyphenylene oxide glass material to prevent voltage leaking between the primary and secondary coils

-

Secondary coil windings are precision wound and trimmed to produce desired output voltage

-

Housing constructed from high-dielectric and impact-resistant material that ensures long life in operating conditions

-

Stainless Steel Spring to resist corrosion

-

High-temp silicone boot stays flexible for easy removal during related component servicing

Intermotor Wire

Designed to Make it Easy

At Intermotor®, our goal is to achieve excellence by pushing for the “plus” — the extra details that set our products above the rest. Intermotor® Import Ignition Wire Sets feature original equipment fit, form and function plus all the extras you’d expect from an industry leader, including factory-installed clips, trays, loom and numbered leads*. With unmatched coverage for ALL import nameplates, we are the import leader by design.

* Factory-installed upgrades are specific to vehicle make and model.

Click to learn more about our Intermotor Premium Import Wire

-

OE-Matched Spark Plug Boots and Distributor Boots provide correct fit, are resistant to fuel and oil contamination and offer a tight moisture proof seal

-

Numbered Leads for easy installation

-

Factory-Installed Anchor Clips

-

OE-matching Factory Loom pre-installed on wire to complete installation

-

Patented High-Gloss Clear Coat